Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 6BT

Brand: CUMMINS

Certification: ISO

Condition: New

Rated Load: 3-6t

Transmission: Hydraulic - Mechanical

Load and Unload Mode: Front Discharge

Walking Mode: Wheeled

Type: Medium-sized Loader

Packaging: box

Productivity: 10000

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Supply Ability: 1000 Pc per day

Port: SHANGHAI,GUANGZHOU,QINGDAO

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

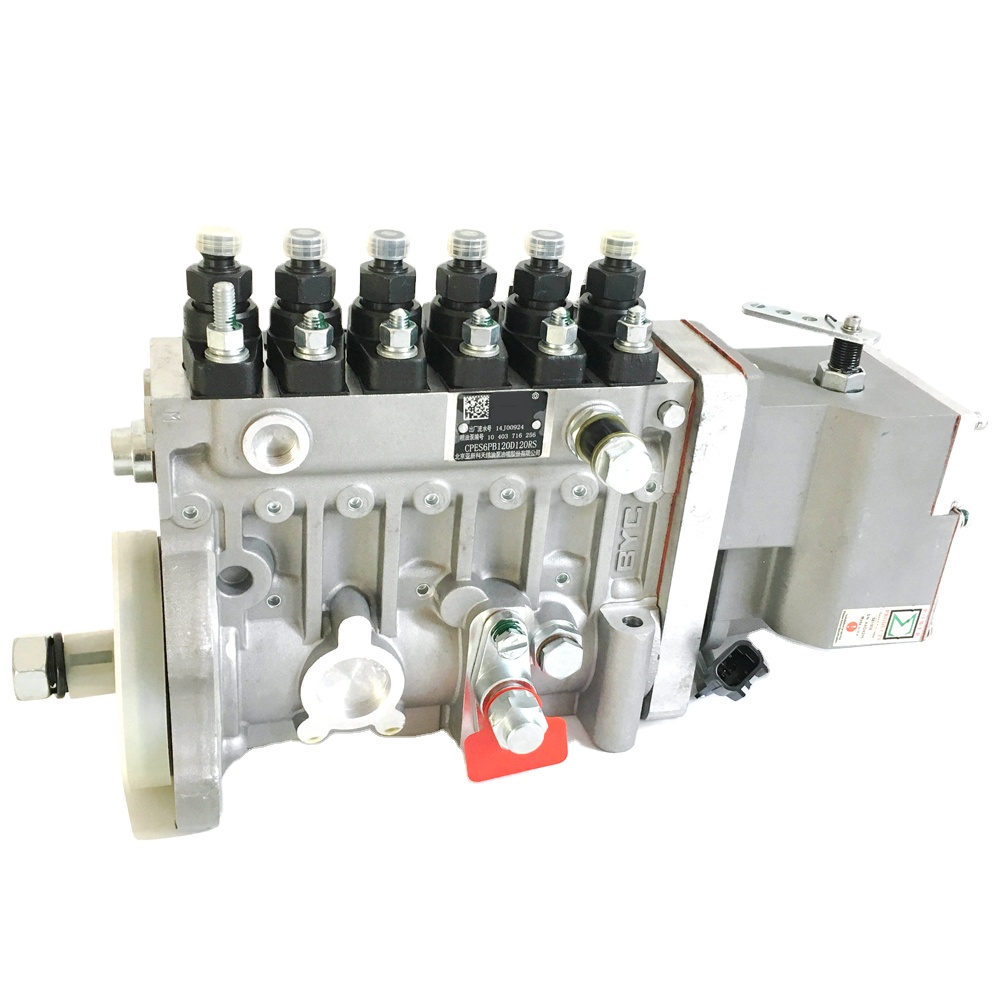

Cummins fuel system size

Common rail fuel system for Cummins diesel Engine (powered by land generator set). The common rail injection fuel supply system is composed of a high-pressure fuel pump, fuel rail, fuel injector, electronic control unit (ECU) and some pipeline pressure sensors. Each fuel injector in the system is connected to the fuel rail through its own high-pressure fuel pipe. The rail acts on the axial hydraulic pressure accumulation of the injector. During operation, the high-pressure fuel pump delivers fuel to the fuel rail at high pressure. The high-pressure fuel pump, pressure Sensor and ECU form a closed-loop operation to achieve precise control of the oil pressure in the fuel rail, completely changing the fuel supply pressure with the diesel engine (land generator set Driven type) The phenomenon of change.

The fuel supply pump sucks the diesel out of the fuel tank and supplies it to the high-pressure fuel pump through the fuel Fleetguard filter. The solenoid valve in the fuel supply pump controls the fuel to reach the high-pressure pump chamber. After the fuel comes out of the high-pressure chamber, it enters the tubular accumulator-common rail . When there is a pressure sensor on the common rail, the fuel pressure is monitored, and this signal is transmitted to the ECU, and the fuel pressure in the common rail is controlled to reach the desired value by adjusting the flow rate. The injection pressure changes according to the operating conditions of the diesel engine (land-based generator set), and then is injected into the cylinders separately through computer control. The common rail not only maintains the fuel pressure, but also eliminates pressure changes, which is beneficial to increase the diesel engine's low speed. Torque and improve low-speed smoke.

Cummins Fuel Injection Pump (High Pressure Fuel Pump)

The fuel is delivered from the fuel tank to the fuel injection pump through the internal supply pump (rotor type), which sends the fuel into the two plunger chambers in the fuel injection pump. The fuel delivered to the plunger chamber is regulated by SCV. The SCV is only controlled by the supply current sent by the ECM. If there is no current flowing to the solenoid valve, the fuel flow is the largest. Conversely, when the current of the solenoid valve is maximum, the fuel will stop flowing. As the diesel engine (drive type for land generator set) rotates, the two plungers create high pressure into the common rail. The SCV is controlled according to the signal from the ECM, thereby controlling the amount and pressure of the fuel supplied to the common rail. In this way, the working condition can be optimized, the fuel economy can be improved, and the emission of nitrogen oxides can be reduced.

Product Categories : Engine System > Cummins Engine Spare Parts

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.